Graco Ecoquip Vapor Abrasive Blast Equipment

Like a carburetor vs.

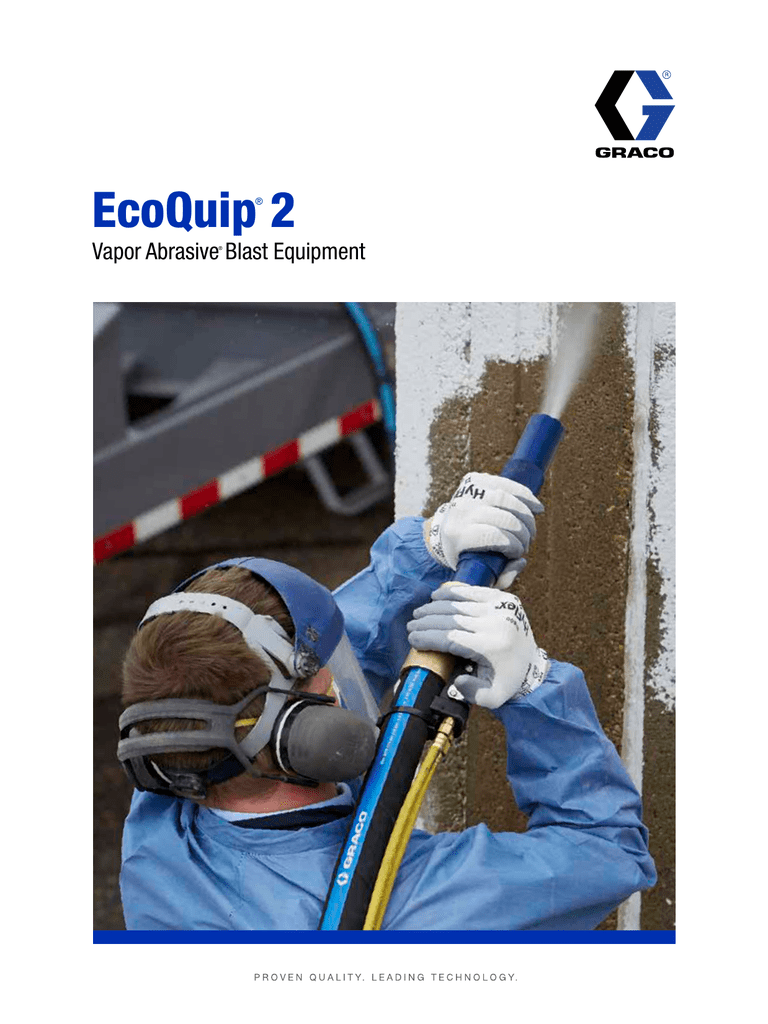

Graco ecoquip vapor abrasive blast equipment. With graco s ecoquip 2 vapor abrasive blast equipment remove everything from paint and coatings to corrosion and residue without the wet slurry mess you get from traditional wet abrasive blasters. Ecoquip vapor abrasive blast equipment 2. The graco ecoquip 2 line of apor abrasie blast euipment is built with your needs in mind. Vapor abrasive blasting is the safer more environmentally friendly and cost saving technology for all of your blasting and cleaning needs.

Blastall is authorized to distribute graco ecoquip 2 vapor abrasive blasters throughout north america. This method is ideal for surface preparation and provides a cleaner surface with little to no embedded particles or clinging dust. Here at m m industrial llc we sell rent and use graco s ecoquip vapor abrasive blasting equipment to make sure that whatever your job gets done with the highest quality equipment and is done right the first time. Fuel injection ecoquip 2 gives you better mileage from your media and.

Graco has recommended the use of green diamond abrasive for use in their ecoquip vapor blast equipment. We have the right model for all sized jobs entry level to mid to high production projects. This method is ideal for surface preparation and provides a cleaner surface with little to no embedded particles or clinging dust. We have teamed up with graco who knows a thing or two about fluid handling.

Continuously blasting a fluid with media and abrasive in it is no easy task. Their answer and esca s to high performance vapor blasting is the ecoquip 2 line. Graco abrasive blasters are ideal for blasting in areas where dust and containment are concerns. Graco abrasive blasters are ideal for blasting in areas where dust and containment are concerns.

In addition we have 30 years of experience as blasting contractors so we know what challenges you ll encounter on the job and we ll get you into the right equipment and supplies to get it done right. Wet and vapour abrasive blast systems employ a mixture of water air and abrasive to clean and remove surface contaminants and coatings. Ecause dust is minimized. In addition graco s vapor abrasive blast equipment reduces dust by up to 92 less than traditional dry blasting and uses very little water making containment and cleanup of debris simple and less messy than power washers.

Ecoquip 2 skid. Wet and vapor abrasive blast systems employ a mixture of water air and abrasive to clean and remove surface contaminants and coatings. If the equipment is not engineered to do this it will lead to flow and productivity issues. Testing conducted by a third party agency shows that vapor abrasive blasting suppresses up to 92 of dust compared to dry blasting.

While competing products draw media and water into the blast stream via the venturi effect ecoquip 2 injects moist media into the blast stream.